APPLICATION

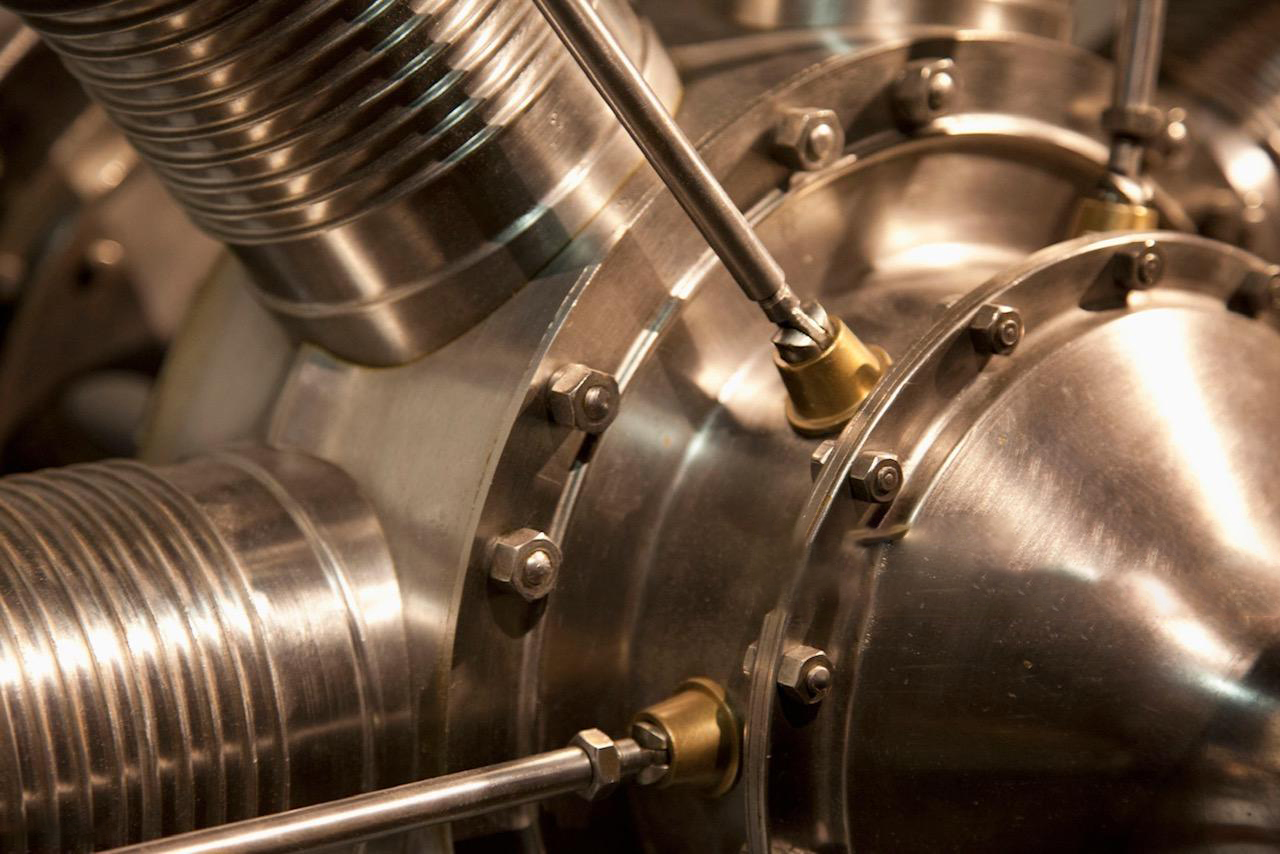

FERRALIUM 255 is a cost effective alternative to materials such as the nickel alloys, 20 type alloys, brass and bronze. Marine environments have long been the domain of admiralty bronze. Alloy 255 is replacing admiralty bronze, and the nickel alloys, in offshore platforms, deck hardware, rudders and shafting.

Alloy 255 is also making inroads in "borderline" corrosion applications where the nickel alloys and high performance alloys have been used but may not have been absolutely necessary. In some instances, it has even been used to replace high performance Ni-Cr-Mo-F-Cu alloys in the phosphoric acid industry.

Valves, pumps, shafts, marine environments, Applications in down-hole, waste water, polycarbonate production, and demineralized water production.