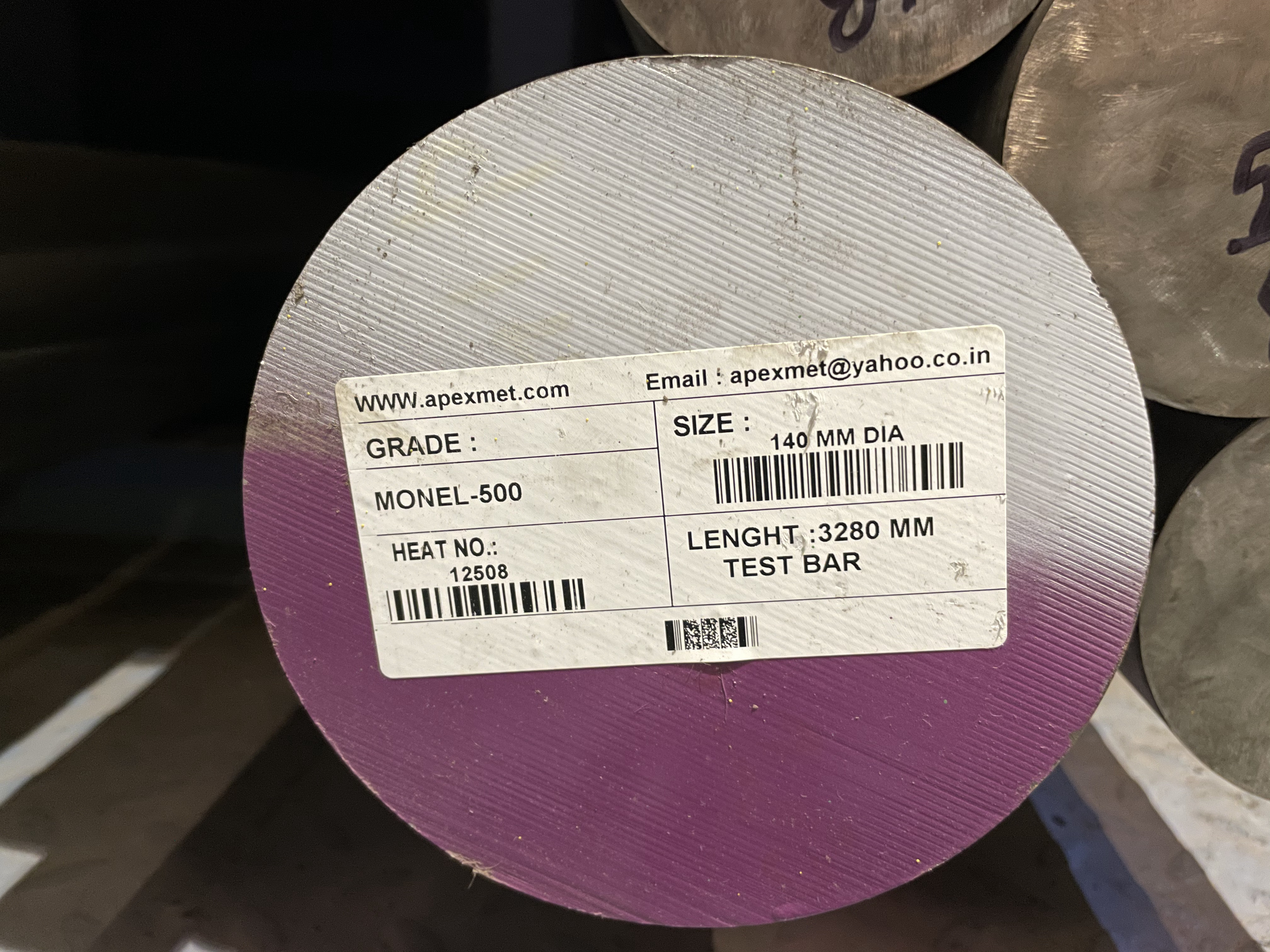

Excellent Quality

Our products are inspected rigorously for a variety of quality attributes to ensure they arrive in perfect condition and without errors.

Global Availability

Proven aility to execute small and large batch orders with an unwavering commitment to on-time delivery.